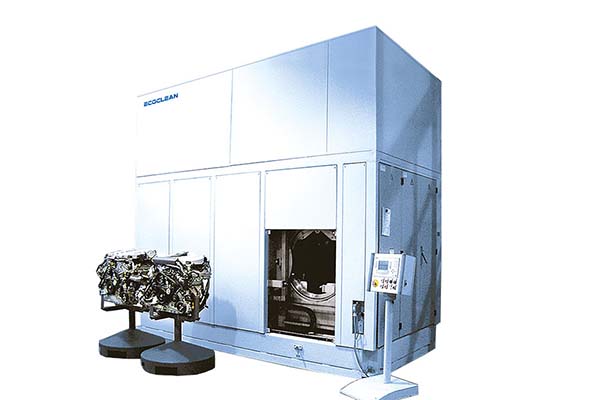

EcoCflex 3 – Outstanding cleaning quality, maximum flexibility and profitability

The enhanced beta version of this flexible industrial cleaning system is the penultimate outcome of 10 years of experience in 450 robotic cell generation.

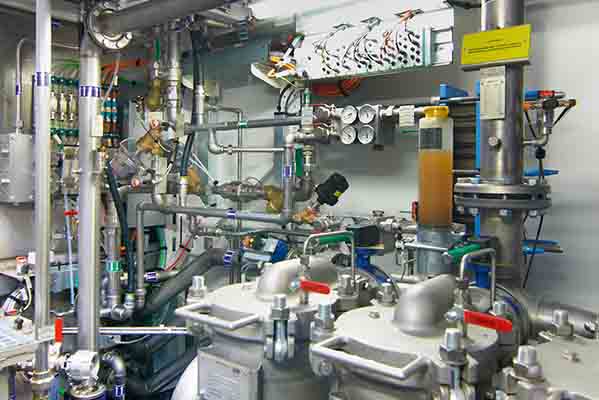

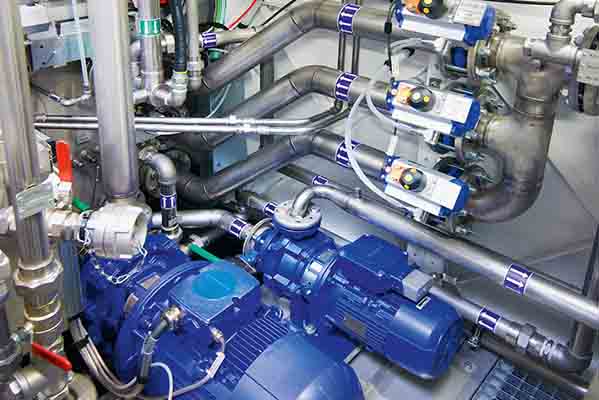

The EcoCflex 3 is an amalgamation of modern flexible SCARA manipulators and the proven cleaning processes – such as injection flood washing, spray cleaning or high-pressure applications. EcoFlex is a flexible Cleaning system that aids precision in parts cleaning with significantly reduced carbon footprint, energy consumption to achieve high standards of technical cleanliness.

The entire control of the machine and the manipulator is carried out via a CNC control.

- The newly developed SCARA-Manipulator ensures the cleaning requirements are achieved to T

- 1 Siemens CNC (840D) takes control of the machine and manipulator

- Load Robot not required

- Consistent use of high-strength aluminum and stainless steel for the plant and the SCARA-Manipulator

- Any cleaning chemical within a PH value between 6 – 10 can be used

- Alternatively use of a 6-axis articulated robot or the SCARA-Manipulator

- Alternatively available as self- or externally supplied 1 or 2 bath technology

- Injection flood washing with the low-pressure slit flood nozzle

- Hybrid nozzle for removing clamp chips and/or deburring under water

- High-pressure turret with up to 6 tools for quick tool change

- Functional transparent system design with best maintenance access

- New SCARA-Manipulator, replacing default loading robots

- Advanced process technology for high standards of precision cleaning

- Benchmark in energy costs and footprint

- Simplified operation with a Siemens CNC control

- Modular lock concept for cycle times from 30“

- One-touch service and optimized maintenance for machine and manipulator

- Noise level smaller 72 dB (A)

Related Products

EcoCcube

Effective spray cleaning for a variety of applications

EcoCflex 3

Outstanding cleaning quality, maximum flexibility and profitability

EcoCbelt

Beltwasher for cleaning processes comprising up to three stages