Mega 86W- Solution for precision demanding applications

Industrial parts Cleaning segment in itself stands by high standards and when precision in minutest of thing is looked for you have the right ultrasonic parts cleaning machine- Mega86W.

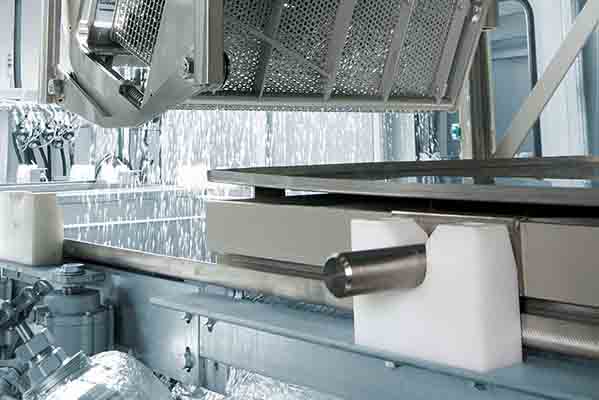

For applications where high throughputs and/ or high-quality end result is desired with fine cleaning Mega 86W is the right machine to deliver. In multistage aqueous immersion cleaning processes, the Mega 86W cleaning system offers an array of options.

With various processes and features available, the Mega 86W industrial parts cleaning system is used for mass-produced bulk items just as successfully as for fine cleaning of injection system parts or medical components.

- Multi-stage wash and rinse process with hot-air drying

- Greater area coverage cleaning regards to immersion cleaning

- Parts baskets can be rotated, oscillated, raised and lowered , which suits best to aid cleaning and drying effect

- Automatic lid placement for parts basket

- Stainless steel pipework

- Waste water-free operation due to integrated treatment unit AQUACLEAN

- Throughput can be increased with extra rotation frames

- Conveyor unit is driven by maintenance free servo motors

- Custom programming of process sequences

- Error diagnosis via plain text display on operator control panel

- Closed system housing with large sliding doors for optimum access

- Automatic conveyor

- Extra rinsing baths

- Filtration units

- Injection flood washing.

- Ultrasonic unit

- Vacuum drying

- Deionization system for rinse water treatment

- Settling tank

- Diaphragm filtration for additional bath treatment

- Automatic dosing unit

- Waste water-free during operation

- Maximum bath life due to continuous treatment

- Minimum energy input due to heat recovery

- Minimum volume of waste for disposal due to concentration of residues

- Low consumption of cleaning media

- Flexible adaptation to throughput and cleaning quality

Related Products

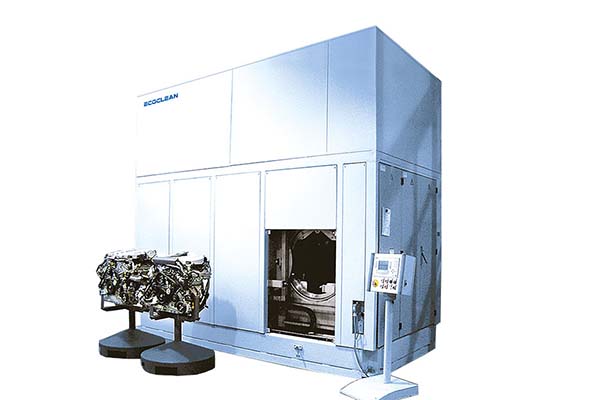

EcoCcube

Effective spray cleaning for a variety of applications

EcoCflex 3

Outstanding cleaning quality, maximum flexibility and profitability

EcoCbelt

Beltwasher for cleaning processes comprising up to three stages